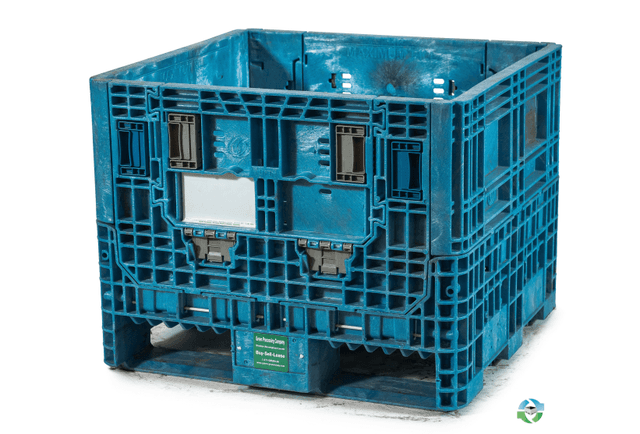

Used collapsible containers as versatile options for smart storage systems

Wiki Article

Discovering the Benefits of Making Use Of Mass Containers in Modern Supply Chains

The use of mass containers in modern supply chains provides a variety of benefits that are entitled to cautious consideration. These containers can lead to significant expense financial savings while boosting logistical performance. They also play an important duty in decreasing packaging waste and enhancing storage services. As markets significantly prioritize sustainability, the potential effect of mass containers ends up being a lot more relevant. What details advantages can be realized by embracing this strategy?Price Financial Savings With Mass Handling

Bulk handling offers substantial expense savings for organizations within modern supply chains. By using bulk containers, companies can reduce product packaging costs substantially, as fewer materials are needed for transportation and storage. This decrease in packaging not just reduces expenses but likewise minimizes waste, straightening with sustainability goals. Additionally, bulk handling makes it possible for extra efficient transportation, as larger quantities can be shipped in less journeys, leading to lowered products prices.Labor costs likewise see a decrease; bulk materials normally need less hand-operated handling, allowing staff to concentrate on other value-added jobs. Moreover, the streamlined storage of mass containers optimizes warehouse room, leading to possible financial savings in functional or rental expenses. In general, implementing mass handling methods can considerably improve a company's profits, making it an eye-catching option for companies looking to boost their expense performance in an open market

Boosted Efficiency in Logistics

While standard supply chain approaches often include fragmented processes, the integration of bulk containers significantly boosts logistics performance. These containers help with the streamlined movement of products, decreasing managing times and lessening the need for several transfers. By settling materials into less deliveries, business can optimize transport courses and reduce overall products expenses.

The improved exposure provided by mass logistics enables real-time tracking of deliveries, permitting supply chain supervisors to respond quickly to any type of disruptions. On the whole, the adoption of bulk containers changes logistics operations, cultivating a more dexterous and receptive supply chain that meets the demands of modern-day commerce.

Reduction of Packaging Waste

As firms look for to boost sustainability in their procedures, making use of mass containers plays a necessary function in minimizing packaging waste. Standard product packaging approaches typically involve several layers, causing substantial waste, both in materials and disposal. By making use of mass containers, companies can significantly lessen the amount of product packaging needed, as these containers are developed to be reused and reused. This change not just lowers the volume of single-use packaging sent to land fills yet likewise lowers the carbon footprint connected with manufacturing and transporting product packaging products. In addition, mass containers assist in much more efficient loading processes, allowing for a higher amount of products to be transferred at the same time, therefore reducing the need for too much packaging. Inevitably, adopting mass containers leads to a much more sustainable supply chain, straightening functional techniques with ecological obligation while additionally potentially lowering prices connected with product packaging waste management.Enhanced Storage Solutions

Reliable storage services are crucial for maximizing supply chain performance, particularly when mass containers are employed. These containers maximize room utilization, permitting greater thickness storage. Their uniform measurements enable piling, which lessens the impact called for in storage facilities and circulation facilities. This organization not just enhances accessibility yet also improves stock monitoring.In addition, mass containers can be developed to suit numerous materials, from liquids to solids, therefore using adaptability in storage choices. Their durable building guarantees toughness, minimizing the danger of damage throughout handling and transportation. why not check here Companies can experience fewer disruptions and reduced substitute costs.

Additionally, the standardization of mass containers helps with easier assimilation into automated storage space and access systems, additionally improving functional effectiveness. Finally, the fostering of bulk containers brings about improved storage space services that sustain streamlined procedures and contribute favorably to overall supply chain efficiency.

Promoting Sustainability in Supply Chains

Promoting sustainability in supply chains has become an important focus for organizations seeking to minimize their environmental effect. The fostering of mass containers acts as a pivotal approach for enhancing sustainability initiatives. These containers, Read Full Report made for efficient storage and transportation, significantly lower packaging waste compared to conventional product packaging methods. By using sturdy products, mass containers can be recycled numerous times, even more decreasing the demand for single-use packaging.Additionally, mass containers enhance logistics by optimizing room usage during transportation, consequently lowering carbon emissions related to shipping. Businesses can also simplify their supply chain procedures, which adds to lowering energy usage. Furthermore, firms that prioritize sustainability commonly improve their brand name track record, interesting eco mindful customers. In general, incorporating bulk containers into supply chains not just promotes environmental duty yet also promotes functional effectiveness, showing an extensive strategy to sustainable business methods.

Regularly Asked Questions

What Kinds of Products Are Finest Suited for Mass Containers?

Products finest suited for bulk containers include grains, chemicals, fluids, and big elements. These items benefit from effective storage space, transportation, and reduced packaging waste, eventually boosting operational efficiency and cost-effectiveness within supply chain processes.

Just How Do Mass Containers Influence Supply Administration Practices?

Bulk containers enhance inventory administration by lowering managing times and enhancing storage space. They enhance exposure of stock levels, streamline monitoring, and promote more exact projecting, eventually bring about improved efficiency and reduced operational prices.Exist Particular Industries That Benefit The Majority Of From Bulk Containers?

Specific markets, such as agriculture, chemicals, and food handling, benefit most from mass containers. used collapsible containers. These markets make use of bulk containers to enhance effectiveness, lower prices, and boost logistics, inevitably streamlining their supply chain operations considerablyWhat Are the Safety Factors To Consider When Using Mass Containers?

Safety and security factors straight from the source to consider when making use of mass containers include guaranteeing structural honesty, proper handling techniques, protected loading and discharging processes, regular evaluations for leaks or damages, and conformity with relevant regulations to minimize dangers throughout transportation and storage.

Just How Can Business Shift to Bulk Container Equipments Properly?

Business can effectively shift to bulk container systems by assessing current logistics, educating staff, slowly applying the brand-new system, reviewing vendor capabilities, and constantly monitoring performance to ensure effectiveness and safety and security throughout the procedure. (used plastic containers)

The use of mass containers in modern-day supply chains offers a range of advantages that deserve careful consideration. By using mass containers, business can lower product packaging prices considerably, as fewer materials are required for transport and storage. While typical supply chain methods usually include fragmented procedures, the combination of bulk containers considerably boosts logistics effectiveness. By utilizing mass containers, businesses can especially minimize the amount of packaging called for, as these containers are developed to be recycled and recycled. Efficient storage space services are important for enhancing supply chain efficiency, particularly when bulk containers are utilized.

Report this wiki page